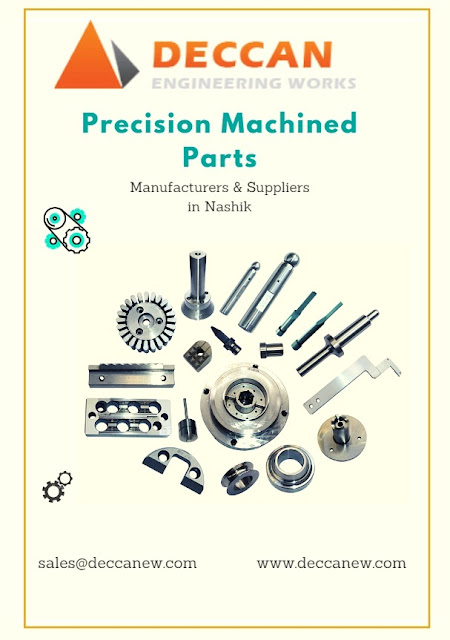

Precision Machine Parts

Precision Machine Parts Manufacturers in India

Precision

machining is the

method of cutting metal parts that suit modern technologies today. Precision

machining is a form of technical manufacturing that is important for the

production and layout of machines, components, equipment, and other hardware

that are necessary for maintaining process controls and tolerances that operate

under very tight specifications.

We at Deccan Engineering Works strive to precisionmachine parts manufacturer & suppliers that are high in

quality to cater all walks of industry. Our expertise is precision machining of

high volume mission-critical components; we also provide medium volume

production on many parts, as well as prototyping. We also customize precision machines parts as per the client’s

requirement and are offered at very cost effective prices.

Precision machining follows the instructions provided by

computer aided design and computer aided manufacturing programs. These programs

and the blueprints enhance the ability to meet tight tolerances. Our precision machined parts manufacturers designs end up as engineered and computer

aided designs, many start out as hand drawn sketches in the initial phases. Precision

machining can be used with a number of raw materials such as plastic, ceramic,

metal, composites, steel, bronze, graphite, and glass. A variety of methods can

be used to make precise cuts and difficult extraction of the raw material. Frequently

used tools include derlin cam, cylindrical cam, bottom cavity extension, entry

bush, double grove scroll cam ,strainer basket, end eye cap, aerospace

components, multi step cam, medical implants, impeller machining, turbine blade

machining.

Below we have

listed some key benefits of precision machined parts:

High accuracy:

A high

accuracy components or tools can be easily manufactured with the help of

sophisticated software such as computer aided manufacturing (CAM) or computed

aided design (CAD).

High efficiency:

The

technical capability of advanced machines and gadgets is much higher than that

of humans.

Saves time

When an

industry needs machined components for its main products, it is always easier

to get them from those specialized in the manufacturing of precision

components.

Reduction in material wastage

During the

production of a component, the amount of raw material wasted is one of the

critical parameters that decide the overall cost of the product. Most of the

material is expertly used in precise machining and thus the quantity of waste

is drastically reduced which in turn helps to reduce the cost.

Our precision

machined parts manufacturers defined precision machining using the

highest function of a tool, program, engineering talent or equipment thereby

pushing the limits of design feature creation and materials science and

performing these operations within the tightest tolerances defined by any

sub-set of these production parameters. To ensure robustness and sharpness,

these precision machine parts are made from quality hardened and angered steel

and high-class steel.

For

more information on precision machining and how it can benefit your business,

get in touch with Deccan Engineering Works.

Contact us: 9657039991

/ (0253) 6646234

Visit us: http://bit.ly/2oOlq9T

Comments

Post a Comment