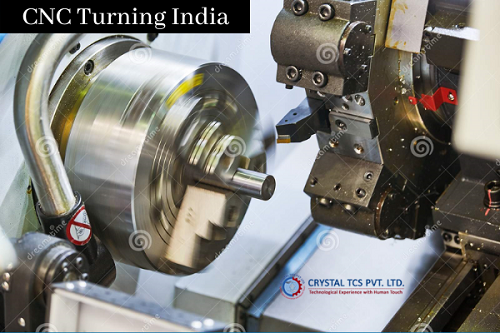

Precision Machined Parts

Deccan Engineering Works Pvt. Ltd. provides precision CNC machining and this route towards cutting metal parts can fit into the current innovation. Deccan spends significant time in the assembly using PCs interrupted by cylinders, motor fuel injectors, and CNC machines. Our goods are used cross side on activities, for example, cars, therapeutic, oil, and gas. We have numerous precision CNC machining manufacturers for high precision machining parts. Precision machining is a method of cutting metal parts that are conducive to today's modern technology. Precision machining is a form of technical manufacturing that is critical to the manufacture and layout of machines, components, equipment, and other hardware required to process, and control that operates under extremely tight features. Our facility is equipped with a CNC machine, which allows us to easily manufacture complex precision machined parts. Our next few devices allow us to better serve our customers. 4-axis machining CNC T