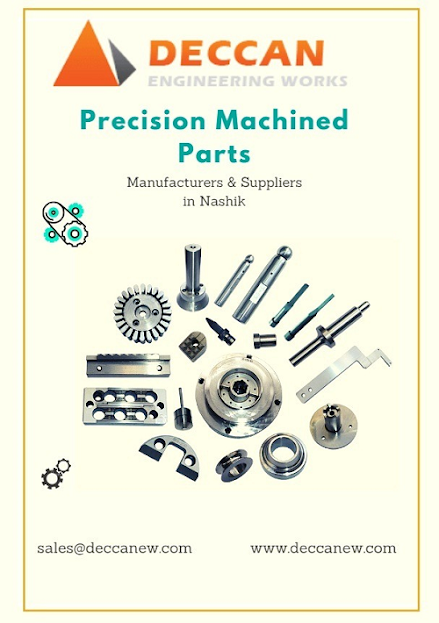

Precision Machined Parts

We strive for precision machine parts manufacturers and suppliers in Deccan Engineering Works who are high in quality to meet all levels of the industry. Our expertise is precision machining of high volume mission-critical components; We also provide medium volume production as well as prototyping on many parts. We customize the exact machine parts as per the requirement of the customers and are offered at a very effective price. Deccan Engineering works on customer drawing and specification requirements to develop the process required to produce precision machined parts from metals and other materials. Our precision machining parts define precision machining using productive tools, programs, engineering prowess, or the highest performance of equipment to ensure strength or sharpness, these precision machine parts are made of quality hardened and tempered steel and high-grade steel. To easily manufacture precision machining parts, our industry is equipped with CNC machines: 5-Axis ma