Deccanew – The manufacturer and suppliers of Turbine blades in India

Deccanew – The manufacturer and suppliers of Turbine blades in India

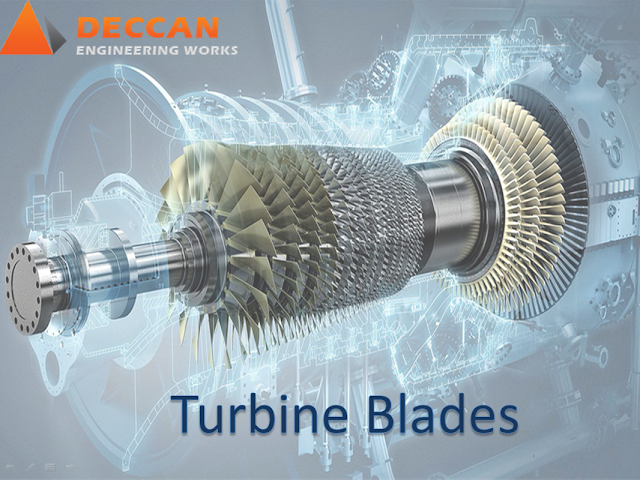

The turbine blade is the component which makes up the turbine section of a steam turbine and gas turbine. Turbine blades are responsible for extracting energy from the high-temperature gas produced by the combustor. Turbine blades frequently use exotic materials like superalloys and different types of cooling such as internal air channels and thermal barrier coatings.

Deccanew brings vast experience of 3-axis, 4-axis or 5-axis and turbine blade machining in India. We are prepared to fully address your requirements with end-to-end manufacturing processes and solutions. We are earned a reputation as a trustworthy company with world-class quality. Our state-of-the-art manufacturing and repair capabilities can be vital to the success and lifespan of your plant. We are supplying high quality blading and components for all gas and steam turbine applications required by service providers and end-users. We are manufacturers and suppliers of turbine blades extensive engineering and manufacturing capabilities for steam turbine blades. Our team delivers on situate, where and when you want it.

Turbineblades are designed for the finest aerodynamics and form of advanced metal alloy castings and composite to increase strength and avoid corrosion. Inaccuracies in blade geometry and positioning may cause energy conversion efficiency loss and unfortunately blade failure. To guarantee the finest position and aerodynamics operation, tight tolerances apply to the alignment of turbine blades. Turbine blades need to be largely effective, which means that engineers must be choosy about their materials. These factors are critical in helping blades remain functional throughout structural loading effects including heavy winds and ice accumulation.

We manufacture turbine blades following a highly structured and controlled process. Constructed from high-temperature superalloys, we manufacture turbine blade designs with geometrically internal cooling passages and cooling hole patterns. Our engineers use CAD/Cam systems and professionals designs and build custom fixtures and tooling. AT many stages of the production cycle as well as prior to the packaging and shipment, we perform numerous test to verify the quality of the material and the blade structure.

With our advanced manufacturing method, our turbine blades exhibit an exceptional level of quality. We supply stage 1,2,3 and 4 blades to major domestic and international gas turbine manufacturers if you required turbine blades for processing contact us today.

Contact us:- 9657039991 / (0253) 6646234

Visit us: http://www.deccanew.com/turbine-blade-machining.php

Comments

Post a Comment