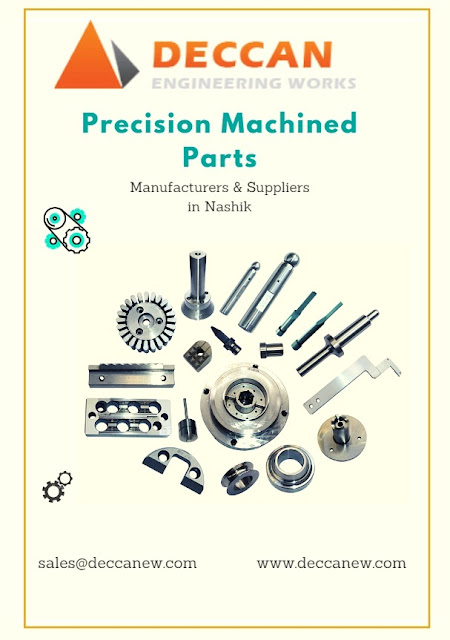

CNC Machining in nashik

CNC Machining for Convention Production Facilities in Nashik CNC is a Computer Numerical Control machine and used to automate machine tools through the use of pre-programmed machine control sequences. This process includes bending, drilling, hole punching, gluing, grinding, laser cutting, flame and plasma cutting, slicing, picking and putting, and ultrasonic welding. Mills, lathes, machining with electric discharge and water jet cutters are often used for CNC. The main concern with the most used CNC machining can be cut in directly proportional to the number of axes that CNC machine operates. The axes on a CNC machine are split into the x- and y-axis tracks (horizontal) and a z axis track (vertical). The most common being a 3-axis machining CNC with tool carousel or 5-axis machining CNC with interchangeable tools. CNC machining is versatile & therefore widely used for production of prototypes, minute tolerances, and secondary operations and post-forming including